“With great power, comes great responsibility…”

Rough day at the office? Equipment issues? Running low on operators, maintenance technicians, show callers or artists due to illness? Well, for all those cast and crew members working in the circus, resident theatres, cruise ships, rock tours or anywhere else in the live entertainment industry, we have all heard the old saying, “The show must go on.”

Interestingly, there is no real explanation of this particular cliché’s origin. A few theories state that it comes from the old circus days, when something was not going correctly, the ring masters would try to keep the public and audience distracted, while also attempting to keep the show running. Nevertheless, this phrase has survived through the years and is still a highly valued phrase today.

It is often a favorite phrase of the decision makers who are ultimately responsible for making the final declaration of whether in the interest of the company or audience, the show goes on stage or part of a performance doesn’t present. There are a variety of reasons of why a show’s integrity could be put in jeopardy, but weather, equipment failure, and safety are some of the more broad reasons for cancelling a show.

It makes sense when such a decision is made, it is made using the appropriate information provided from all people involved.

Anyone working in the venue has the right to flag a potential issue or ask for a stop in the show should they deem it necessary due to an abnormality, discrepancy or a possible threat to the cast, crew, audience or equipment.

These team members could be the rigger, stage crew, operators, coaches, artistic directors, stage managers, operators, and even artists. Following the flagging of an issue, an inquiry and investigation should then take place.

Some issues can be identified, agreed upon and resolved quickly while others could require deeper investigation, discussion and could become a show stopper. Regardless of the reason, all voices involved must be heard. Monetary and marketing impacts cannot be and should not be the final deciding factors. Nobody wants to see a major show alteration or cancellation.

While, undoubtedly, everyone wants to put together the best show possible for the audience that paid their hard earned money to come watch you and your team earn yours, but to what point? And at what cost is it not worth the risk?

Is it possible to continually impress the audience, but still keep the cast, crew and spectators safe? Absolutely. This is where the experts in each field step up and industry standards are designed, discussed and broken down by teams of professionals from many different areas throughout the entertainment industry. Thanks to organizations like Entertainment Services and Technology Association (ESTA) and American National Standards Institute (ANSI), these types of standards exist and are reviewed on a regular basis to see if improvements are necessary due to faults or failures during the use of these standards throughout their existence.

However, it takes an entire industry to implement and follow these standards and keep incidents and near-misses to a minimum. There are many ways to keep incident reports, injuries and fatalities to a minimum, but following the standards set by the experts in our industry is key.

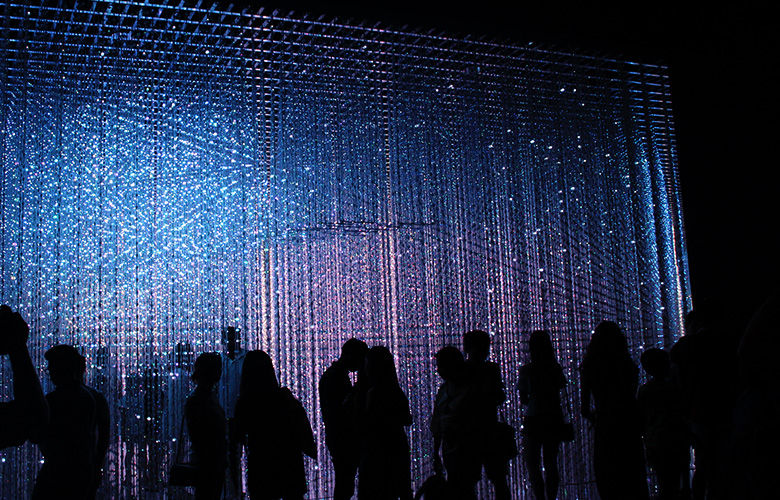

With technology in the entertainment industry evolving at an incredible speed and shows continuing to use equipment that is bigger, stronger and faster than ever before, it would bode well to ask the question, does “The show must go on” cliché still apply to all aspects of the entertainment industry?

Or is it time that this phrase is updated to meet the industry’s current condition, along with the standards and demands of the organizations, employees and patrons that represent it? Technology is enhancing our industry’s ability to shock and awe the audience, but due to increases in speed, power and xyz movement capability, there should in turn be a reciprocal effect to the corresponding risk assessments solely due to an increase in risk factors. The higher the risk assessment, the more preventive precautions need to be put in place to bring the risk factor down to an acceptable level.

For example, for the automation operator; does an increase in overall velocity, decrease in acceleration time and deceleration time not decrease the amount of time allotted for the operator to react to either an artist being in the wrong position or the machinery moving in the wrong direction? Sure it does. What happens when the size of an LED wall is increased? In most cases, this would increase the amount of active components and the power requirements of the LED wall.

Arguably, this doesn’t change how you work safely on this particular piece of equipment or the safeties that are put in place to keep your RA in the green, but more power requires more voltage or more amperage, ultimately increasing the risk. You get the idea. The bigger a system gets, the more costly and complex it becomes to operate and maintain it thoroughly and safely.

What if a required standard doesn’t exist in the area that your theatre is built or your tour is visiting? It is rare to find a place in the world today that doesn’t have some sort of standard for the entertainment industry, but there are still a few places out there that do have loose standards or no standards at all and you may be required to work there.

So, what do you do? What is expected of you by the rest of the industry? Well, this is definitely a decision that needs to be decided by the department heads and management teams. Or maybe even someone as high up the food chain as the General Manager. Standards are everyone’s business and it is best that everyone has an input on how their equipment is installed, maintained and operated, no matter where in the world you may be.

This is why most touring shows either meet the standards or are well above the areas in which they tour. If they do reach an area that has specific standards, then it is their obligation usually by law to find a way to meet those requirements or forfeit a part of the show to avoid packing up camp completely. Usually, this is not the case as most tour companies have full-time employees tasked specifically to research each site’s rules, laws and regulations long before the tour enters the country.

If you do find yourself in an area that does not require certain standards, then the most important thing is that you find a standard that everyone agrees will work for your situation, implement it and stick to it.

It is probably best that the entire technical team follow the same standards. This would assist in the simplification and organization across departments of the Standard Operating Procedures (SOPs) and aids record keeping. All standards demand record keeping to ensure that maintenance and inspections are being done in a correct and timely manner. Record keeping is not just a great tool to remind you when maintenance is required or past due, but is also beneficial in the event of a near-miss or incident. Records are not just for the safety of the cast and crew, but also for the company.

In the case that no standards or poor standards existed in an area that you’re working, it still gives no one the right to unintentionally put the cast, crew or audience in danger. This includes the local crew. If you find your local team members are not meeting the established standards, make sure you explain to them what is required of them during their time within your department.

If they can’t follow suit, get them off the site. You can’t follow the locals around all day, so if they don’t want to comply, you have two choices, speak to their supervisor or get rid of them. This may be easier said than done, but most people working for local crews are willing to learn from an expert and will understand your reason for administering rules. If we are lucky, this requirement for safety will spread and stick with each team encountered and will eventually embed the area with thoughts of safety, ultimately saving lives.

Find a standard, agree on the standard, implement the standard, follow the standard and record. Even better, find a standard and kick it up a notch. Take all the requirements of the standard and go one step further.

Requirement is an inspection once a week, try and inspect twice a week. Tough to do, but overall worth it.

There are a significant number of different standards out there and the documentation on these standards are becoming more and more available to the public free of charge.

Within many standards, there is an unwritten paragraph; “If a human is allowed the room to make a mistake, then a mistake will eventually occur.” In other words, the complex movements (cues, multi-targets, etc.), processes (velocity, ramp, acceleration, position, sensor, feedback, etc.) and safety (emergency stops, logic functions, soft limits, hard, limits, faults, etc.) aspects of the systems must be left to the machine as much as possible.

This reasoning is most certainly why some of the newer standards exist. Standards exist in order to cut down on near-misses, incidents, injuries and fatalities within the industry. Unlike laws, standards are not legally binding, but instead certain rules are put in place to allow the companies to be informed of how to conduct business safely and efficiently. As per the Technical Standards Program (TSP), “These standards prevent accidents, protect lives and property, save time and money, solve problems, inform the industry, and enhance creativity.”

Even though there are some technicians too proud to admit it, there are always going to be places in show programming where an operator is left with the ability to fail due to the repetitive responsibilities that they have been tasked with and our human nature of complacency and imperfection.

Repetitive being the key word. The more you operate the more chance you have to make a mistake. It is a numbers game and eventually, an operator will miss a cue.

This is not necessarily wrong or dangerous as there are many compelling reasons of why we still use and prefer human operators over full machine control. However, due to a human’s capability to make a mistake, it is highly imperative that we follow the standards to the best of our abilities, while continuing to make standard operating procedures, cue stacks, maintenance practices, and testing procedures (to name just a few) resolute, but malleable.

Documentation is to be strong in its existence, but designed to be reviewed and updated whenever deemed necessary for continuous improvement throughout the life of not just a show, but the industry itself. Another famous cliché, “Hindsight is always 20/20.” So instead of waiting for a unsatisfactory outcome to happen, we must always continually question and update endlessly each and every process.

If this is the case, then what do we leave the machines in charge of? Well, there are a couple of things that must be left in the analogous and digital hands of the machine. These requirements are usually stated within the confines of the standards mentioned earlier, but for the benefits of this article I will mention a few. The crucial ones being safety and repeatability. Repeatability is a must and heavily relied upon by the artists and crew to know exactly how a system is going to feel, perform and act while they are giving it their all on stage.

If something is different every single show, you will have one edgy artist or crew member. Trust me, you will hear about it. This is why it is super critical that the artist and crew are the final step in the validation process. Safety is key and the best part about a machine is it won’t get mad at you or lose interest in its responsibility if it is left on twenty-four hours a day.

Not only are the integrated safety systems very quick to respond, but they are your 24/7 watchdog for issues or faults within the system.

If you employed a human to do these checks, it would take hours, instead it is all checked and re-checked in the blink of an eye. I am not saying take the inspections and maintenance out of the equation. These are a must, but you can feel safe knowing that these safety systems are designed to continuously check your software and hardware for any signs of fault, failure or degradation.

If it finds a fault within the system, one of three things will usually happen depending on user settings and the safety requirements of the system. Either the system will notify the user of its finding or it will immediately stop the system or both. It is imperative that on these systems that you listen to the machine when it says there is an issue. The machine is set up to only see 1s and 0s and it knows when something is not correct.

If it’s off, don’t override it unless you absolutely know it is safe and something or someone can replace the failed component. Professionals make a career out of traveling around the world fixing entertainment systems that have been damaged beyond repair due to the safety systems being overridden.

A great example of increased integrated safety systems being introduced into the entertainment industry has been taken from a chapter out of the manufacturing industry. This was introducing something known as Safety Integration Level 3 or SIL 3 into the automated scenic, lift and performer flying systems. The higher the SIL level, the higher the associated safety level, and the lower probability that a system will fail to perform properly. As the SIL level increases, typically the installation and maintenance costs and complexity of the system also increase.

Increasing safety levels within the entertainment industry with such protocols as SIL 3 will make it much harder to unsafely bypass these systems thanks to a heavy increase in logic based safety components. In some venues, the automated scenic and performer flying systems have even added on load cells and dual-encoder feedback loops for each individual axis.

Dual-encoders are utilized for optimal safety, as each encoder is monitored separately and then cross-checked with each other to ensure exact position, velocity, acceleration and deceleration. Meanwhile, load cells are used to decelerate and stop an axis almost immediately which will put it into a ‘fail-safe’ status should the load cell detect any load above or below the range set within its parameters. Newly instated initiatives such as these are being put in place to keep incidents to a minimum and save lives.

Due to our predecessors’ relentless hard work and requests for improvement, there have been a copious amount of electronic companies in the manufacturing industry who have designed hundreds of self-checking safety components, which detect anything from light, temperature, force and pressure to object proximity, position, and even magnetic fields.

Each safety component can allow for safety processes to be relayed up to several hundred times a second with the capability of either simple or complex feedback to the operators depending on the application.

With these type of devices becoming more available and affordable, it is best to leave as many safety processes as fully automated as possible.

This will put the numbers game back in the human operator’s favor, not to mention the rest of the cast and crew.

Leaving the rapid-response check-back and logic functions to the intelligent systems, also requires that adequate redundancies are put in place. Intelligent systems now have what are considered as self-checking capability. This means that the safety components will not only be sending a signal out to all of its distributed systems for status feedback, but it will also be sending signals and running logic functions on its own internal components up to several times a microsecond to ensure its own full functionality.

A safety system is no good, if it itself has failed. Self-checking is not a redundancy, as it will simply shutdown the system by putting it into an emergency stop status. This emergency stop status will be different for every system, but as per most standards the emergency stop status will always be described as being in a ‘fail-safe’ state. In other words, the system will fail in a safe inoperable condition until full-system functionality is restored. For stage machinery, this would mean, system off and brakes closed. At this point, it is up to your well planned and practiced contingencies and preinstalled redundancies will be put into action.

For any show from the local theatre to the mega-shows on the Las Vegas strip, there are two main reasons that human operators will always be used and those reasons are purely human unpredictability and a machine’s ability to fault or fail. Now, it is not a shot at anyone to say that humans are not predictable. However, it is merely impossible for a cast of artists or stage crew, no matter how professional they may be, to be in the same exact position every single cue, for every single show, every single day without fail.

Whether it be wooden set piece that simply has a dog stuck in the track and won’t move or a quick change gone wrong due to a broken bra or zipper or be it a cast member backstage chatting away and misses their cue. Point being is, until you take all human risk factor out of the system completely, human operators will always be required.

A final position defending a human operator over a machine operator is the fact that humans have the ability to see something beyond the feedback systems and repeatability that the machines cannot.

We have the ability to see emotion or even the smallest of things that are out of place, long before a machine would be able to detect it.

A dancer slightly off her lighting mark while not having the best of runs, a painful wince on the face of straps artist who cannot seem to make it into their rollup or a stop signal given by another artist when something just isn’t right. Machines do not and will not have these capabilities to a point that they will be trusted over a human show caller, operator, or stage crew anytime soon.

This is a question that can spark quite the debate amongst technicians, operators, managers, engineers, and integrators. It is the opinion of some that there is a bit of responsibility and power that needs to be left with the operators and technicians themselves. As discussed, this is one of those reasons that machines are not left in charge at the end of the day, humans are.

Overriding can be left at the discretion of an operator as long as a few things are understood. Clear guidelines and SOP’s need to be in place and agreed upon by all operational team members. A significant amount of training, experience and understanding should be considered prior to bypassing a safety system of any kind.

Overriding a system will require more than just the operator. If a system is not responding due to a fault or failure, even if the exact component is known, usually the component is not within the operator’s grasp. Another team member will be part of resetting the system and teamwork will be required. Feedback and communication from the field technician being crucial. If it can be overridden by the operator, then the fault is temporary and not necessarily a critical one, but you are still taking a risk by trying to continue after an error has already occurred once.

When it is not worth the risk? It takes an entire industry working together to make that kind of determination. Despite this, standards won’t ever be so specific that they will help you make a decision about every single situation. That is when you have to listen to all of your available teams and make the best decision possible.

It is better to make decision albeit the wrong decision, as long as it is a decision that has optimal safety in mind. There is no middle ground between safe and unsafe. It’s either safe or it’s not. For all those decision makers out there that like to echo the phrase, “The show must go on,” to motivate their teams, take heed.

Overall, prior to any given show, all risks must be assessed continuously with safety in mind. This can be achieved through the following of industry standards, leaving complex motion, processes and safety functions to the intelligent systems, keeping human operators at the helm, in the integration of improved safety systems as they become available and frequently reviewing your own internal processes for continual improvement.

Even after all of that, there are still going to be those days in any venue, where something has caused the status quo to change and you need to ask yourself the following questions. At what point is the performance not worth the risk? At what point do we produce a new phrase for a new time. “The show CAN go on, SAFELY.”

Jay Withee has had an interesting and multifaceted 20-year career in the entertainment and theatre industry working with companies such as TAIT, Cirque Du Soleil and Dragone. Currently, Jay is the Head of Services & Support – Asia for TAIT in Hong Kong. Prior to joining TAIT in 2019 as a Controls Engineer, Jay was the Technical Show Manager with Dragone at The House of Dancing Water at the City of Dreams Resort in Macau. At The House of Dancing Water, Jay held the roles of Automation Operator, Lead Automation Operator, Assistant Head of Automation, Head of Automation and Deputy Technical Director. Jay had been involved with The House of Dancing Water since its installation and creation, enjoying all the complexities that were involved in bringing this large-scale production to life and operating it on a day-to-day basis. He has been involved with other creations of similar scale including Cirque du Soleil’s KA at the MGM Grand in Las Vegas. Jay started his technical career working for the cruise industry, spending almost five years on the ships. In this time, he held the position of Automation Technician, Field Service Engineer and Rigging Specialist, while getting the opportunity to assist on some of the largest theatrical installations sailing the high seas today, including Royal Caribbean’s Liberty and Independence of the Seas. A graduate of ECPI University, Jay earned his Bachelor of Science in Electronic Engineering with a major in Mechatronics. In his spare time, Jay has chaired the Entertainment Technology division of the Professional Advisory Board for St. Clair College in Windsor, Ontario, Canada and been a member of the Industry Expert Advisory Group for Millersville University in Millersville, Pennsylvania. Jay has also had the opportunity of being part of the TheatreArtLife start-up team. Jay lives in Hong Kong with his wife Anna and two kids, Tyler and India.

Read Full Profile© 2021 TheatreArtLife. All rights reserved.

Thank you so much for reading, but you have now reached your free article limit for this month.

Our contributors are currently writing more articles for you to enjoy.

To keep reading, all you have to do is become a subscriber and then you can read unlimited articles anytime.

Your investment will help us continue to ignite connections across the globe in live entertainment and build this community for industry professionals.