Putting on an outdoor show itself has its challenges, and that’s before you even start to put actors on the stage.

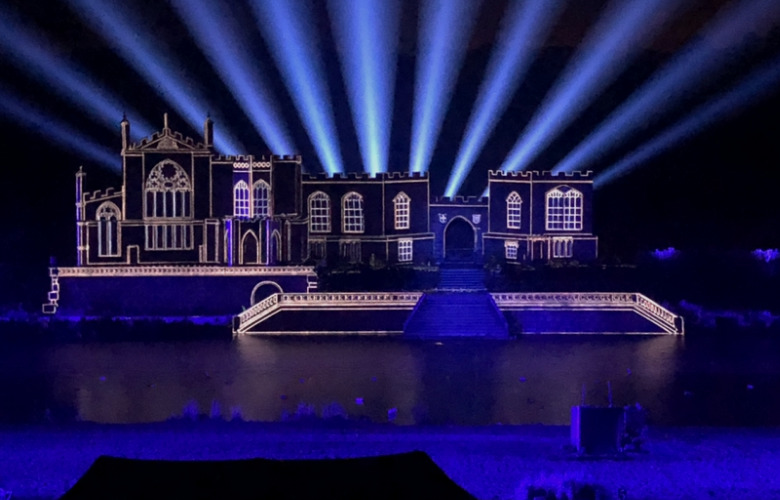

Now combine this on a 7.5 acre acting area encompassing a lake with a catwalk for actors to walk across, underwater set elements hydraulic controlled, fire effects from underwater set pieces, projection mapping using 14 Barco projectors on a hydraulically lifted castle set piece at maximum distance, pop up tents, water effects including a projection mapped water curtain, 3 technical hubs for show operation housing all the hydraulic elements, complex show control systems & a very large firework pyrotechnic display as part of the show & snow machines! And not to forget the H&S side of the water we add in 4 Scuba Divers for show operation and safety.

If that wasn’t hard enough to manage for a show, you then add the fact that only yourself and 2 others are full time staff. The rest of the technical team which requires 18 people to run at a minimum are all volunteers with tech not being their primary career. Yes so, all the cast and the techs and everyone show based is a volunteer. Kynren is the show with approx. 1000 cast/tech/FOH members, with around 600 on stage including children.

I was the Technical Director for the show and the site, an exhilarating exciting time in my career. Coming into the show in the April and only seeing what the show would look like from a video of the show recorded from a camera. I took the challenge on and had an amazing time. As a volunteer myself back at the start I know what it was like when someone was very forthcoming with information and willing to share their knowledge and train in systems. It is with this that myself and my technician and electrician we set forth and provided the training to the team on the systems. Put all the lighting and sound element back in, realigned the projectors. Carried out essential maintenance on all the systems. (All tech elements are removed after show season). A process that took 2 months to complete, yet as the volunteers had full time jobs most of the training to take place in evenings and weekends.

A complex operation which only performs for the public 6 times a year in the summer. A 90 minute show telling the history of England.

For me it was interesting to see how others had managed the operation before and how best to ensure the longevity of the show and the technical systems given the small operational usage per year and the detrimental effects the environment and water has on the systems. A fine balancing act and keeping calm under pressure is key to the job.

Being TD for not just the show but the rest of the site was a new challenge and one that I embraced. Prior to my arrival the show and the entire site was running off 2 x 800kVa Generators. This was switched over before rig check. The generators started and switched from mains to generator. This was hard to get my head around, the reasoning behind it was that the show that Kynren is based on is in rural France where the power is not reliable.

I however felt that both the cost and environmental impact of using the generators was too much, given that after some research there had never been a power outage in the time the show had been on site.

All the control systems, amps, LED lights, show control and all consoles were already on a 4 min UPS supply. Therefore, we added some more UPS supplies for the critical show operation lighting, so that a show could continue until power restored.

I then had the generator switch changed for an Automatic Transfer Switch run from the Deep Sea Electronics panel, which in the event of power failure would start both generators and transfer the load to the gen sets. A process when tested took 25 seconds.

The automatic switch back to mains was disabled as for operational that needed to be a manual.

This was a massive cost saving activity as the cost of the electric to run the site was less than a ¼ the cost of purchasing the diesel to run both sets for the entire night.

All of this and the show operation could not happen without an extensive maintenance program which we had made electronic as paper records rarely maintained and maintenance history on items are near non-existent. A process that took several weeks we tagged all the Assets on the site with barcode and built an inventory system using CMMS software by Fiix. Once set up regular work orders were created for systems, generator checks and weekly testing. Reports were done on computers in the office or via the app which made maintenance very efficient.

Techs as well the tech volunteers had access and could look up history of work done, or parts replaced in an instant by scanning the QR Code on all the assets.

I had an amazing time working on the show, as well as working with very hard-working dedicated volunteers. The ability to give back knowledge to others is very satisfying.

Family Life Vs Ship Life: Balancing Life & Work on Cruise Ships

Gareth is a Technical Director based out of London in the United Kingdom. He started his career as a light technician and has worked as stage manager, production manager, company manager and technical director. Gareth's credits include Production Manager for Secret Cinema, Technical Director for Kynren by Eleven Arches, Production Manager for Royal Caribbean International specialising in Aquatic Venues. Was Technical Manager for Virgin Voyages, Chief Electrician at Zorro UK Tour & London and The Lion King on the West End. Gareth is now Technical Director For Atlantis Events which is gay & lesbian firm that charters full cruise ships.

Read Full Profile© 2021 TheatreArtLife. All rights reserved.

Thank you so much for reading, but you have now reached your free article limit for this month.

Our contributors are currently writing more articles for you to enjoy.

To keep reading, all you have to do is become a subscriber and then you can read unlimited articles anytime.

Your investment will help us continue to ignite connections across the globe in live entertainment and build this community for industry professionals.