Some effects just can’t be delivered by existing machines, and sometimes you must invent a solution for a particular show. Whether you are part of the globally known water show or a local small theater company, whether you are an engineering company or an isolated skilled technician, there is the fact: you are already running out of time when the solution does not exist yet.

Here are some working habits we implemented in my team to make the best of our time.

In engineering, time is not linear. Brainstorming, feasibility studies, reformulating what is essential, boiling down raw ideas… all this preliminary work is beyond valuable. There is no shame in spending 25% of the available time just to find the optimized angle of attack. This is where you can make as many mistakes as you can, while there is still time.

At this stage, making mistakes is free. For example, choosing the right location for an accessing door while you are doing CAD is easy. Milling, drilling and welding a patch on the field when the item is already integrated is another story.

The cruel thing about this early stage is: you cannot rush this.

Engineering is not a sport, it is a mind game, and the mind works in a strange way. Working double shifts does not make the brain produce more good ideas.

I hardly get creative and productive more than 40 minutes in a row. Past that, I need to do something else. I never found any providential solution at 11 pm after a whole evening thinking and sketching about it. However, it happened many times that after a good night of sleep, the right idea pops up sparkling clear in the morning. If you get stuck on the design this early in the process, no worry. You need to be qualitative first of all. You will rush later.

I have odd memories of some meetings, where we were looking for inventing the next revolutionary pulley. Or what would make any bolt obsolete. Deep down, when looking for a solution, any technical enthusiast dreams of coming up with the revolutionary system. It is a healthy habit, it means you are questioning the standards and the obvious, and that is the start of any great outcome.

But let’s be reasonable on this. How many prototypes do you need to get that crazy idea real? If your timing is short, the specs are clumsy, and the budget is tight, it’s no time to be an outlandish inventor.

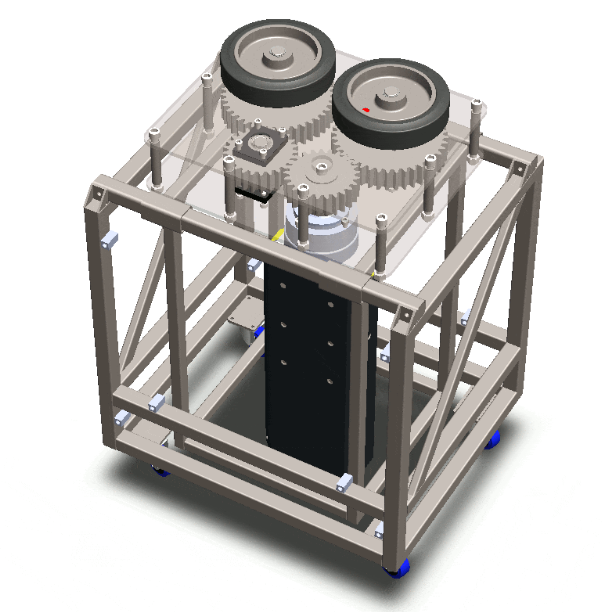

Your system will be an addition of functions. If one fails, you are in trouble. Then, keep things simple, use proven systems and assemble them.

Nowadays, engineering is mostly about assembling skills. Back in the days, good engineers were expected to design their own bolts, and choose the right pitch themselves. Now that we have the standards, today’s engineers are expected to assemble existing elements and sub-assemblies in the fastest and smartest way.

Despite all the honorable efforts CAD software companies put into making digital models as insightful as possible, let’s face it: there is nothing like good old prototypes. Prototyping costs time and money but can save even more. Virtual design is a filter to the most experienced and the best trained engineer. Prototyping is not just about “risky” ideas, it is also useful for the simple cases.

While you have been focusing on the complex functions, you might have missed the basics. And, suddenly, your brand-new electronic board destroys at first switch on. Or your mechanism works but cannot be assembled. Here, the prototype is a tangible quality check.

Programmers know that better than others: do it, try it, do it again. Prototyping is the key. Prototype often, quickly, and simply.

Having your first prototype to be your final deliverable is a pretty risky game. But what if you have no choice but delivering a prototype?

There is a difference between believing in your idea and being convinced that nothing can break it. Your idea has flaws. Many. Sometimes, you just have too little time to go through enough prototypes, and you know the thing might not be functional until the last moment.

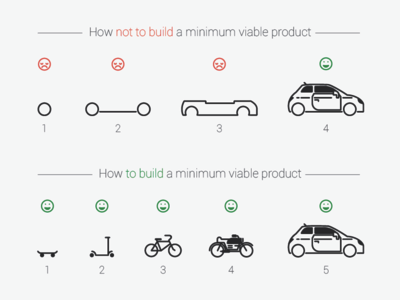

Some years ago, when we were starting the business, my professional environment was a lot more about entrepreneurship than it was about engineering and entertainment. I came across that smart concept, which lean start up gurus are much enthusiastic about:

I feel uncomfortable with this sometimes. What if no one cares about the skateboard? What if my mission is to get the car ready right away? If so, there will be many functions with possible flaws, and an increasing chance of failure during the shows.

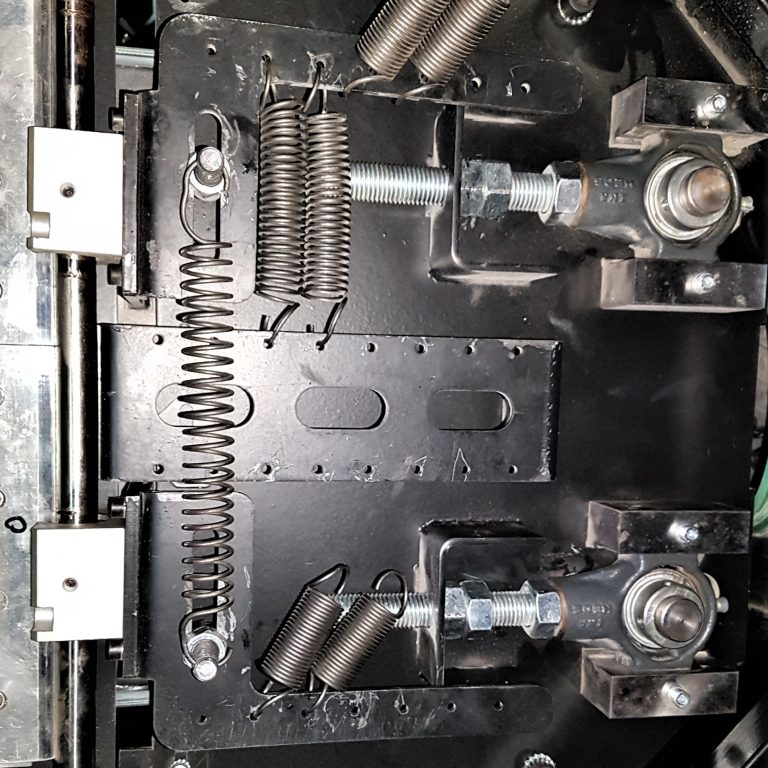

Whenever we have a doubt on a feature, we immediately pre-design a backup plan along with the main solution. It saved the day more than once.

Pre-designed means: with hand tools, you can work your way around it if you are stuck on the field. In practice, it can be leaving some extra volume for a future add-on, ease access in one particular spot, pre-drill to have fixation options, prepare spare I/O connections etc.… It is not necessarily complex, but it is a bit counter intuitive. You must believe in your idea while you are acting like it would fail. You are running out of time and maybe you are designing functions that will not be useful in the end. But you don’t know that yet.

Short timing is no excuse for having no plan B. So, have that idea of yours you love so much go through the polygraph test, and get to work on how you will save the day once that idea fails. It’s more fun than it sounds.

To be continued…

Also on TheatreArtLife:

The Show Must Go On: Or Does It?

Large Scale Automation Programming With Dave Ball

Performing arts and science enthusiast since its childhood, Matthieu Guichon studied simultaneously drama acting and mechanical engineering in France. He started his career as a design engineer in the set workshop of the Lyon Opera House, where he developed CAD workflows for set building, sustainable construction methods and structure optimization. In the context of opera projects, Matthieu discovered machine design and started volunteering on some side projects where machines had to be invented from the ground up. After majoring in entrepreneurship, Matthieu co-founded ExMachina SAS in 2014, an engineering company with the full mechatronic skillset dedicated to the entertainment industry. Ever since, he leads the business development and works on the mechanical aspects of ExMachina’s challenges. Much eager to share knowledge and explore the evolutions of technical jobs in the entertainment field, Matthieu teaches in engineering and art schools about set design and mechatronics, respectively. He is also part of a discussion group analyzing ecodesign techniques and mindsets, together with technical teams of most national theaters and operas of the country. During the last five years, Matthieu worked on more than 30 projects with his team, mainly for operas and theater, but also for outdoor installations and events. Inspired by new management and economical models, Matthieu is always seeking more efficient and relevant teamwork synergies.

Read Full Profile© 2021 TheatreArtLife. All rights reserved.

Thank you so much for reading, but you have now reached your free article limit for this month.

Our contributors are currently writing more articles for you to enjoy.

To keep reading, all you have to do is become a subscriber and then you can read unlimited articles anytime.

Your investment will help us continue to ignite connections across the globe in live entertainment and build this community for industry professionals.